|

India To Create Board To Evaluate Medical Devices

India’s Department of Health Research (DHR) is planning to

establish a Medical Technology Assessment Board (MTAB) to evaluate all types of

new and existing medical technologies.

The MTAB will foster the development of medtech innovations

that will help reduce healthcare costs, improve patient care and streamline the

medical reimbursement procedures. Pharmabiz.com cites sources that claim steps

already have been taken to set up the board and get it operating, though no

specific timetable is mentioned.

The 12th Plan Working Group on Health Research recommended

the establishment of an MTAB. After considering the recommendation, India’s

government decided to create the MTAB to evaluate the need and cost

effectiveness of new and available medical technologies in the country,

pharmabiz’s sources added.

The government plans to consult technology generators,

industry, regulators, economists, user groups and experts knowledgeable about

similar models from the United Kingdom, Canada, Australia, Thailand and other

countries before establishing the MTAB. The new agency will be a part of the

overall regulatory / promotional structure being established in the DHR to

accelerate indigenous production of health products/instruments / medical

devices.

As part of the initiative, a Memorandum of Understanding has

been signed between the DHR and the National Institute of Clinical Excellence

(NICE) in the United Kingdom. The two entities are now identifying areas where

they can collaborate on and exchange knowledge about NICE regulatory (first

phase) procedures. An Apex Advisory Committee to set up the board has been

formed and is functional, sources added.

A Parliamentary panel also has called for early action in

setting up the MTAB. “The MTAB is proposed to be assigned with very critical

activities. However, the reply of the Department does not indicate any time

frame within which the MTAB would become functional. A timeline may be fixed for

completing the task,” the panel said.

(Ref:

http://www.mpo-mag.com/contents/view_breaking-news/2014-03-20/india-tocreate-board-to-evaluate-medicaldevices/)

Antimicrobial Plastics Market:

Healthcare / Medical Sector Is By Far The Indisputable Winner

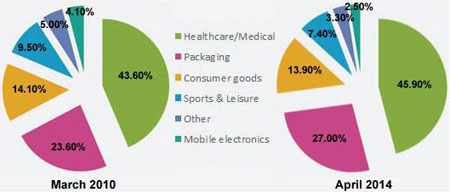

Undoubtedly the Healthcare/Medical sector emerges as first

consumer of antimicrobial, far ahead of packaging according to the recent Click

‘N Vote ‘For which market will the use of antimicrobials grow the most?’ 2014

results are on line with the 2010 click N’ vote results as shown on the Figure 1

below.

Figure 1: Market to Witness Highest Growth in

Antimicrobials Comparision of March 2010 {220 votes} & April 2014 {122 votes}

Results) Gathered from SpecialChem4Polymers Community Results of the Survey

In fact those similar results hide an intricate and dynamic

evolution due to new trends: more stringent requirements, higher demand,

government regulations, wider range of products used every day, new

environmental trends, new additives, specific solutions. These various

industrial sectors have very different requirements as varied as safety,

lifetime increase, aesthetics, unpleasant odor suppression and sometimes simply

marketing arguments.

Devices are as heterogeneous as medical devices, packaging

products, sports and recreation equipment, Food processing machinery, business

machines, consumer appliances, general household goods, transportation

interiors, construction supplies, outdoor applications and compounds that use

organic fillers.

In addition to technical and economic requirements, the

growth of antimicrobial plastics depends on specific legislative pressures. In

the United States, usage and benefit claims are regulated by the EPA or guided

by the FDA depending on usage. In Europe, The Biocidal Products Regulation (BPR,

Regulation (EU) 528/2012) concerns the placing on the market and use of biocidal

products. All biocidal products require an authorization before they can be

placed on the market, and the active substances contained in that biocidal

product must be previously approved.

All antimicrobial agents have different activities and

varying influences on microorganisms, so every type of antimicrobial solution

must be studied separately depending on the microorganism(s) to be fought.

Antimicrobial solutions include, for example, inorganic

derivatives of Silver, Copper, Zinc and organic products such as BIT (Benzisothiazoline-one),

DCOIT (Dichloro-octyl-4-isothiazolin-one), OIT (Octyl-isothiazolin-one), OBPA (oxybisphenoxarsine),

IPBC (iodopropynyl butylcarbamate), TBT (tributyltin), TBZ (Thiazolyl

benzimidazole), Triclosan, Zinc pyrithione... Of course nanomaterials are also

used and studied.

As for other new and growing technologies, there are many

controversies concerning the antimicrobial spreading in the environment, the

possible harmful effect of certain entities notably for long-term use, the

possible bacterial resistance and/or hormonal disruption, the efficiency of some

products in preventing illness and curtailing infection.

Healthcare / Medical Sector:

Complex epidemiological situation, nosocomial infections,

microbial contamination, and infection risks in hospital and dental equipment

have led to an ever-growing need for prevention of microbial infection in these

various areas.

Antibiotic resistance is a serious and growing phenomenon and

has emerged as one of the pre-eminent public health concerns of the 21st

century. A World Health Organization report states that this serious threat is

no longer a prediction but is happening right now in every region of the world

and can affect anyone, of any age, in any country.

Prevention technologies are vital weapons in the battle

against infection and antimicrobial solutions help enhancing infection

prevention and control. A growing interest in recycling some disposable medical

products continues to create opportunities for antimicrobial solutions.

Antimicrobial solutions are used in hospitals, dental

surgeries, care homes and GP practices for products ranging from beds, cubicle

curtains, nurse call systems, wall and ceiling paints, floors, door handles,

handrails, pull cords, and case note holders.

(Ref:

http://www.specialchem4polymers.com/community-pulse/communityinsight.aspx?id=10677

)

|